EPMA-8050G - Características

Electron Probe Microanalyzer

Unprecedented Spatial Resolution

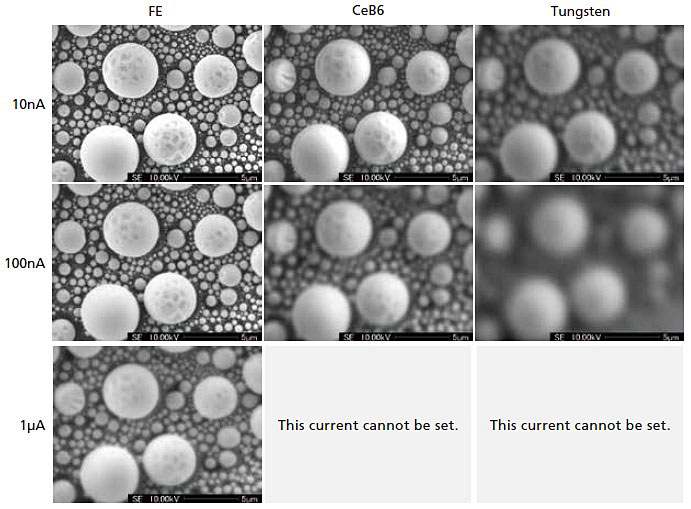

The system offers the ultimate in secondary-electron image resolution under the beam current conditions used for analysis. (With a 10 kV accelerating voltage, 20 nm at 10 nA / 50 nm at 100 nA / 150 nm at 1 μA). The results are very clear in comparison to a conventional electron gun (CeB6, tungsten).

The same resolution image can be obtained with a dramatically larger beam current than with a conventional electron gun, so extremely high sensitivity X-ray analysis can be performed.

A further point of interest is SEM imaging with a 1 μA beam current. Only the EPMA-8050G provides a beam current of at least 1 μA, and moreover, finely focuses the beam to this point.

Comparison of Electron Gun Beam Characteristics (10 kV accelerating voltage)

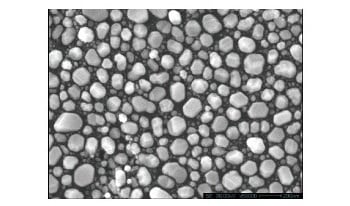

Highest Secondary-Electron Image Resolution of 3 nm

This is a sample observation of gold particle deposition on carbon. A maximum resolution of 3 nm (at 30 kV) is achieved. The beam is focused even at a comparatively large beam current, so a smooth, high-resolution SEM image is easily obtained.

Large Beam Current Enabling Ultra High Sensitivity Analysis

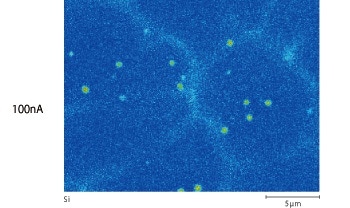

In SEM and EPMA with the FE type, this system's uniquely large beam current (up to 3 μA with a 30 kV accelerating voltage) dramatically enhances the detection sensitivity for ultra trace elements. This enables ultra trace component imaging in element mapping.

In addition, there is no need to replace the objective aperture across the entire beam current range, so the analysis process can be fully automated, with no concerns about axis offset.

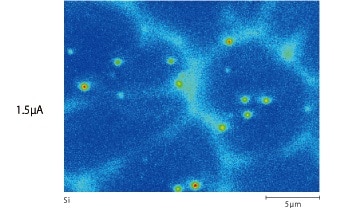

These three images show the results* of a mapping analysis of approx. 1 % Si in stainless steel, using different beam currents. The roughness decreases as the beam current increases, enabling the areas containing Si to be precisely identified.

* In all the measurements, the accelerating voltage was 10 kV, and the sampling interval was 50 msec.

The measurements required approx. 1 hour.

Up to Five High Performance 4-Inch X-Ray Spectrometers Can be Mounted

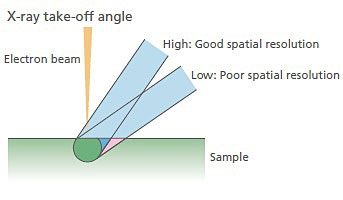

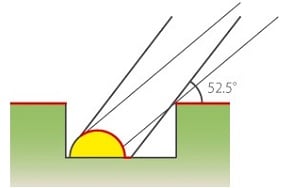

Maintains the 52.5° X-ray take-off angle that is fundamental to analytical performance.

High sensitivity caused by low X-ray absorption

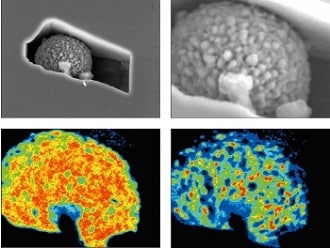

A high X-ray take-off angle also reduces the absorption effect when the bottom of a deep hole or the foreign matter in a hole is analyzed for examples.

Analysis data for foreign matter in a pit. Bottom-left is the distribution of iron (Fe); bottom-right is the distribution of titanium (Ti). The high take-off angle used by the EPMA-8050G ensures highly accurate analysis of rough samples.

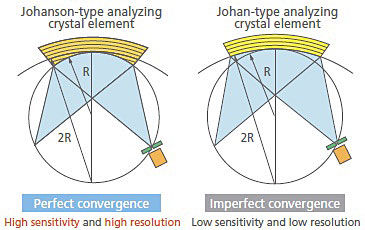

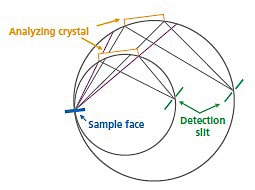

Johanson-type analyzing crystal achieves perfect convergence.

Shimadzu applied its unique crystal manufacturing expertise fostered through the company's long traditions to offer analyzing crystals that deliver both high sensitivity and high resolution. The Johanson-type analyzing crystal achieves perfect convergence with no aberration.

EPMA-8050G accommodates up to five 4-inch spectrometers that offer both high sensitivity and high resolution.

The Rowland circle radius in the X-ray spectrometer is an important factor affecting the EPMA analytical performance. Increasing the radius of the Rowland circle by one inch reduces the detection sensitivity by more than 30%. Shimadzu EPMA instruments accommodate up to five 4-inch spectrometers to cover the entire spectral range.

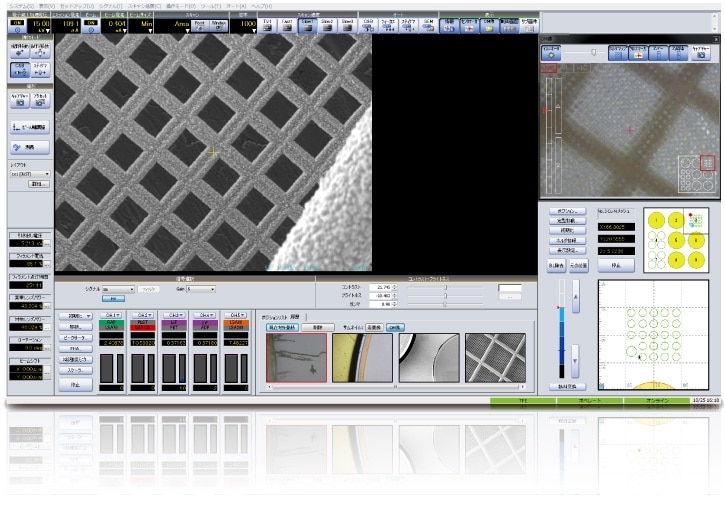

Simple and Easy-to-Understand Operations for All Analyses

This system is equipped with a number of new functions to enable simple and easy-to-understand operations. These include advanced operational performance, with all operations controlled using just a mouse, as well as a user interface designed to be easy to understand, and a built-in easy mode analysis. While easy enough for even novices to use, it also supports sophisticated analysis by experienced users.

- Easy operations for everything from sample mounting to report generation

- Even novices can easily perform everything from sample searching to SEM imaging.

- Unprecedented operability dramatically heightens operational efficiency prior to the start of the analysis.

- Visually, the user interface is designed to be easy to understand.

- Equipped with an easy mode analysis that automates all processes up to generating reports.

Advanced Technology Enabling Ultra High Sensitivity Analyses of Minute Areas

1. High-Brightness Schottky Emitter

A high output Schottky emitter with a larger tip diameter than ordinarily used in SEMs is adopted for the FE electron gun. A stable electron beam is obtained that while bright has the large current indispensable for high sensitivity analysis.

2. Special EPMA Electron Optical System

The electron optical system has a proprietary configuration and control method (Japan Patent No. 4595778). The condenser lens is set as close as possible to the electron gun. Crossover is formed not with the condenser lens but with an iris lens, with the objective aperture arranged at the same position. While this is a simple lens configuration, a large current can be obtained. At the same time, the angular aperture can be optimally configured under all current conditions, minimizing the electron beam diameter. Naturally, there is no need to replace the objective aperture.

3. Ultra High Vacuum Evacuation System

A two-stage differential evacuation system has been adopted, partitioned at the orifices between the electron gun chamber, intermediate chamber, and analysis chamber. Minimizing the orifice between the intermediate chamber and analysis chamber limits the flow of gas to the intermediate chamber. The electron gun chamber is always maintained at an ultra high vacuum level, stabilizing emitter operation.

4. X-Ray Spectrometers with High Sensitivity

The system can be equipped with up to five 4-inch X-ray spectrometers which provide both high sensitivity and high resolution.

The 52.5° X-ray take-off angle enhances the spatial resolution of the X-ray signal, while enabling high sensitivity analysis with minimal X-ray absorption by the sample.