MIV-X - Características

MAIVIS Ultrasonic Optical Flaw Detector

-

Shimadzu's proprietary light imagining technique

-

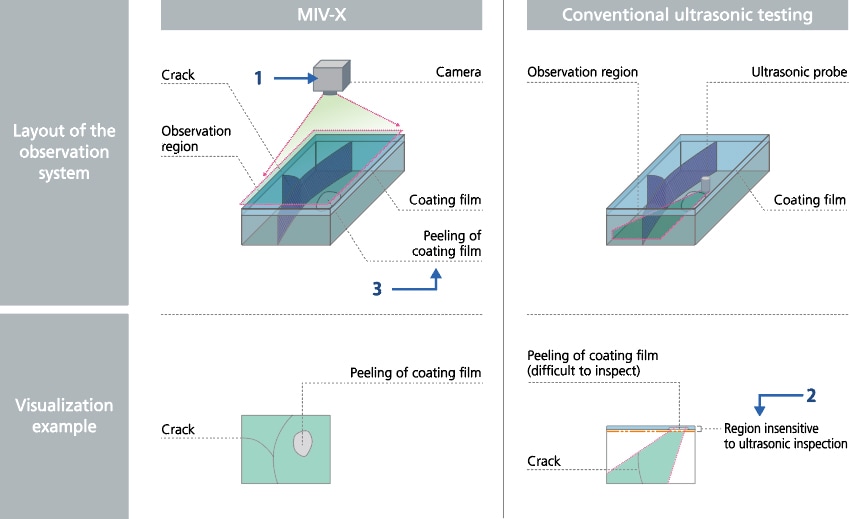

Difference from Ultrasonic Flaw Detection

-

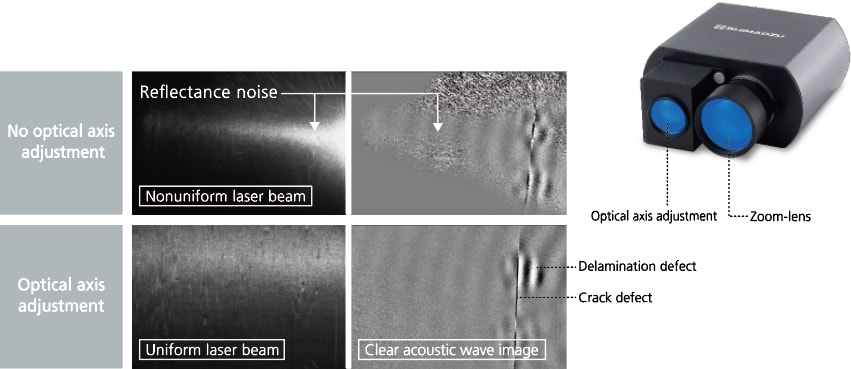

Noise Removal Function Simplifies Defect Identification

-

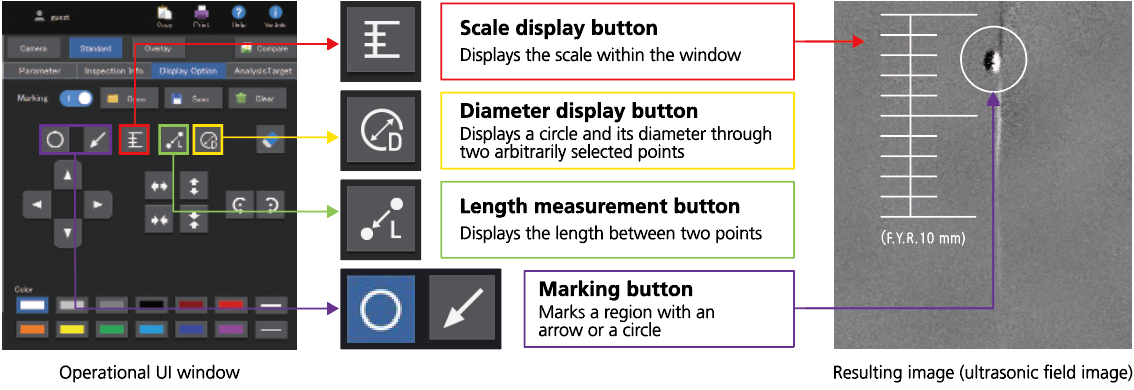

Dimension Display and Marking Functions Simplify Identification of Defect Position and Size

-

Optical Zoom Set (Optionally Available) for Detecting Smaller Defects

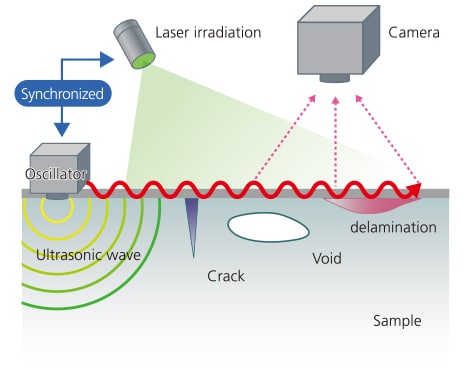

Shimadzu's proprietary light imagining technique

With ultrasonic optical flaw detection technology, the sample is encouraged the displacement of the surface is detected optically,

and the propagation of the ultrasonic wave on the surface is observed.

- The sample is loaded by continuous ultrasonic vibrations.

- Microscopic out-of-plane displacement of the surface due to propagation of the ultrasonic wave is visualized optically using laser irradiation and a camera*.

- Defects are detected by observing disturbances in the propagation of the ultrasonic wave.

*Shimadzu's proprietary light imaging technology combines speckle shearing interferometry via ultrasonic vibration with a stroboscopic technique.

(Patented in Japan, China, and the USA)

Difference from Ultrasonic Flaw Detection

The MIV-X Ultrasonic Optical Flaw Detector assists with regions where ultrasonic testing (UT) is difficult. Leave the non-destructive inspection of surfaces and near surfaces to MIV-X!

Here are the advantages!

- Batch inspection of a wide area within the camera’s field of view

- Good at inspecting surfaces and near surfaces

- No need to worry about differences in acoustic impedance even for dissimilar materials

Noise Removal Function Simplifies Defect Identification

Noise Removal Function Simplifies Defect Identification

Dimension Display and Marking Functions Simplify Identification of Defect Position and Size

Dimension Display and Marking Functions Simplify Identification of Defect Position and Size

Optical Zoom Set (Optionally Available) for Detecting Smaller Defects

Optical Zoom Set (Optionally Available) for Detecting Smaller Defects

Decreases the minimum detection size by a factor of approximately two (MIV-X standard: From approximately 1 mm dia. to 0.5 mm dia.)

Laser optical axis adjustment is also possible, improving irradiation uniformity