Tensile Test Methods for Plastics: ISO 527 and JIS K 7161

Resin materials (plastics) are found in a wide variety of items used on a daily basis. Recently, plastics have started to be used as structural materials in transportation equipment, such as automobiles and aircraft, due to their strength and light-weight nature. In these applications, it is important to understand the mechanical strength properties of these plastics. ISO 527 and JIS K 7161 outline methods for testing the tensile strength of plastics and other resin materials. Included in these methods are accuracy specifications for the test frame and test accessories. The contents of ISO 527 and JIS K 7161 are basically the same, but differ from the equivalent ASTM standard for tensile testing of plastics, ASTM D638. For more information about ASTM D638, please click here.

TRViewX Non-Contact Digital Video Extensometer

Test force accuracy of ±1%

ISO 527 and JIS K 7161 require a test force accuracy that meets ISO 7500-1 Class 1 and JIS B 7721 Class 1, accuracy within 1% of the indicated test force.

Shimadzu’s AG-X plus series, AGS-X series, and EZ-X series test frames and load cells meet the test force accuracy requirements of ISO 527 and JIS K 7161.

|

|

|

| AG-X plus Series High-Performance Test Frames | AGS-X Series High-Throughput Test Frames | EZ-X Series Compact Test Frames |

Elongation measurements with 1 μm absolute accuracy and ±1% relative accuracy are required.

SIE-560SA Automatic Extensometers

ISO 527 and JIS K 7161 recommend dumbbell-shaped specimens with a gauge length of 50 mm or 75 mm, with the 75 mm gauge length added to the 2012 revision of ISO 527.

For extensometers used to measure tensile modulus of elasticity, ISO 527 and JIS K 7161 require the ability to measure gauge length changes with ISO 9513 Class 1 accuracy, within 1% of the indicated displacement.

Dependent on the gauge length of the specimen used, this relative accuracy requires the following absolute accuracy:

- 75 mm gauge length specimens (1A specimens) require absolute accuracy of 1.5 m

- 50 mm gauge length specimens (1A specimens) require absolute accuracy of 1 m

(Specimens with 10 mm and 25 mm gauge lengths are also possible)

Shimadzu’s SIE-560SA series automatic extensometers, TRViewX non-contact digital video extensometers, and SSG-H and SSG strain gauge extensometers all comply with the accuracy requirements of ISO 527 and JIS K 7161. In particular, the SIE-560SA series enable automated extensometer arm attachment and removal, increasing testing efficiency and minimizing differences between operators.

|

|

|

| SSG-H Strain Gauge Extensometers | SSG Strain Gauge Extensometers | TRViewX Non-Contact Digital Video Extensometers |

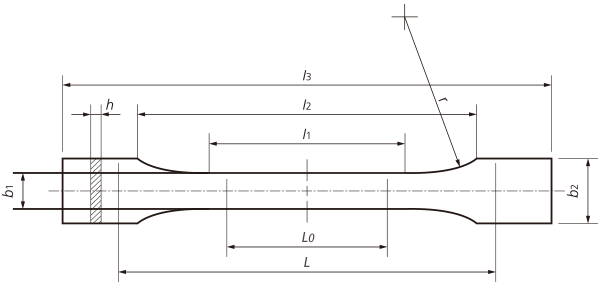

ISO 527 and JIS K 7161 Specimen Dimensions

| Size | 1A Specimens | 1B Specimens | |

| Full length, l3 | 170 | 150 | |

| Parallel length, l1 | 80 | 60 | |

| Gauge length, L0 | 75 | 50 | 50 |

| Parallel section width, b1 | 10 | 10 | |

| Thickness, h | 4 | 4 | |

| Grip section width, b2 | 20 | 20 | |

| Grip face length, L | 115 | 115 | |

Grips, grip faces, and additional devices

Plastics come in a wide variety of types and strengths, depending on the ingredients, mixtures, and composition used. For instance, in structural materials, plastics can be pliable or rigid. There are also many types of engineering plastics and plastics used in composite materials, such as carbon fiber reinforced plastics (CFRP). To ensure tensile strength tests are performed properly, suitable grips, grip faces, and additional devices appropriate for the given material and testing efficiency must be selected. Shimadzu offers a broad line of accessories to support plastics tensile testing, such as grips ranging from manual non-shift wedge grips to pneumatic and hydraulic versions, and axial centering systems.

|

|

|

|

| Manual Non-Shift Wedge Grip | Pneumatic Flat Grips | Embedded File Teeth Grip Faces | Axial Centering Systems |

Sampling rate

For ISO 527 and JIS K 7161, the sampling rate for data acquisition must be at least as high as the sampling frequency, which is dependent on the properties of the material and accessories. For example, for a material with a gauge length (Lo) of 75 mm, a grip face length (L) of 155 mm, a minimum extensometer resolution (R) of 0.0005 mm, and a test speed (v) of 1 mm/min, a sampling frequency (f) of 22 Hz (46 msec) is required.

|

f |

:Sampling frequency(Hz) |

|

v |

:Test speed(mm/min) |

|

L |

:Grip faces length (mm) |

|

Lo |

:Gauge length (mm) |

|

R |

:Minimum resolution of extensometer(mm) |

Resolution must be at least half the extensometer accuracy.

AG-X plus series, AGS-X series, and EZ-X series test frames exceed the sampling rate requirements for such tests.

Strain calculation method

ISO 527 and JIS K 7161 specify the following method (Method B) for calculating strain for tensile tests in which a yield point is present.

Notes: They also include the previous method as Method A. Method B is preferred for plastics with a yield point.

|

εy |

:Yield strain |

|

ΔL* |

:Increase in grip space after yield strain |

|

L |

:Initial distance between grips |

Standard functionality in Trapezium X, Shimadzu’s dedicated materials testing software, enables straightforward calculation of tensile strain for plastics which exhibit a yield point.