Tensile Strength of Polypropylene

●Introduction

In recent years, a variety of synthetic resins have been put to use in a very wide range of fields.

Of these, a number of types of polypropylene have been developed since its production started in 1962, thanks to its excellent heat resistance, chemical resistance, and insulating properties.

The scope of utilization is broad, including bumpers and other parts in the automotive field, electrical components, daily use items, and packaging materials.

With this sort of widespread application, it has become important to examine the properties obtainable from the material on a variety of fronts.

In this example, a typical polypropylene material is subjected to tensile testing at slow speeds.

●Tensile Tests at Slow Speeds (Static Tests)

A tensile test at slow speeds was performed using the Shimadzu precision universal tester Autograph AG-X. (Fig. 1)

Strain between two reference points was measured using a extensometer midway at a crosshead speed (loading speed) of 5 mm/min.

Afterwards, the extensometer was removed, and the sample was loaded until fracture.

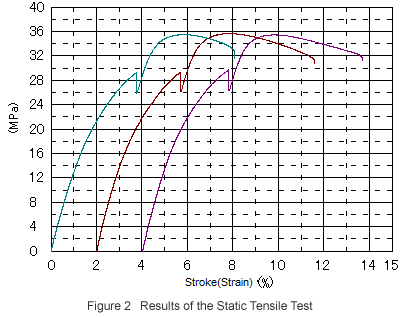

The results obtained in this test are provided in Fig. 2, which shows the relationship between stress and strain.(The results for 3 test pieces are shown with the origin offset.)

Here, the temporary drop in stress at just under 3% strain is due to the process of temporarily stopping the loading and removing the extensometer.

However, it is evident that stable results have been obtained with good repeatability.

Further, the tensile strength (average) is 35.7 MPa, the up edge elastic modulus (average) is 1,265 MPa, and the absorbed energy is 0.49 J.