Observation

SPM Basic Knowledge Q&A

Q2-1: What kinds of samples can be observed using SPMs?

| A: | Any solid sample with a surface, and which can be held in the sample holder can be observed. |

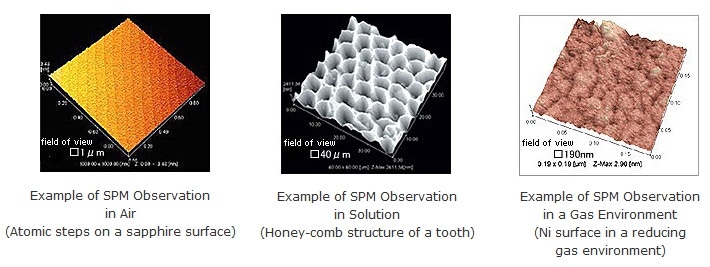

SPMs can be used to observe the surface of solid samples whether in air, liquid, or gas environments. Examples of sample observations in air, liquid, and gas environments are shown here.

SPMs are best suited to observe hard, smooth samples. For such samples, good images can be obtained by simply placing the sample horizontally in the sample holder. Samples that require special consideration include those with surfaces that change quickly, unsecured samples, samples with a secured base but with a loose surface, surfaces that start lifting up over time, and surfaces with a large aspect ratio (ratio between the width and height of the cross section structure, such as the bottom of a narrow deep groove). It may not be possible to observe such samples, or they may require special care with respect to observation and interpretation.

Furthermore, the available performance of SPM systems (resolution, reproducibility, and the ability to obtain non-contour signals) varies significantly depending on a number of factors, such as the sample origin, the surface treatment method, the securement method, the atmosphere near the sample, the type of cantilever used, and individual differences between cantilevers. In particular, significant expertise is required to determine how to properly secure powders and other especially small samples, how to split samples to observe their cross section, and how to prepare biological and other soft samples.

It would be an overstatement to claim that anything can be observed with a SPM. Therefore, in research it is important to sufficiently understand the operating principles and characteristics of the SPM, and to prepare samples appropriately for the instrument (including the hardness, securement method, target area exposure method, and proportion of target material), so as to fully utilize its performance capabilities. These considerations are the same as for other analytical instruments.

Q2-2: What size of samples can be observed using SPMs?

| A: | Typically about 10 mm to 20 mm across when using instruments intended for small samples. |

Models for small samples are generally designed to move the sample with respect to the probe. In such systems, any sample can be placed in the sample holder (usually about 10 mm to 20 mm across) as long as it does not protrude from the holder. Typically, samples from about a few mm to 10 mm in height can be placed in the holder. The figure below shows the actual loading of a sample holder on a SPM for small samples. One concern about this type of SPM is that the edges of the sample holder are often unobservable because the image is obtained at the probe position on the tip of the cantilever. Consequently, it is important to position the area of interest near the center of the holder. Small samples, powders, or biological samples are secured to a substrate, such as glass, mica, or a silicon wafer. It is essential that the surface being observed is roughly horizontal.

Placing a Sample in a Shimadzu SPM, with the

Sample Holder (15-mm Diameter) Held by Tweezers

Q2-3: What is the approximate observable area and magnification range of the SPM?

| A: | The observable diameter ranges from 100 nm to 100 µm, and the magnification range is about 1,000x to 1,000,000x. |

The observable range is determined by the operating range of the scanner that scans the sample or cantilever in the XY plane. On commercial SPM systems, the scanner is generally replaceable. Therefore, the scan range (i.e. observable range) varies depending on the scanner used. (The Shimadzu SPM-9700 has four types of scanners available, which includes optional scanners.) The maximum scan range of the most typical scanner is about 30 µm x 30 µm. In other words, the horizontal observable field (X,Y) is a 30 µm square area. In contrast, the movement range in the vertical (Z) direction (height) is only about 5 µm.

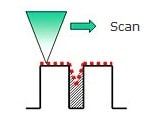

If a maximum observable field is required, a large scanner is available for scanning large areas with maximum (X,Y) values over 100 µm. The maximum value in the vertical (height) Z direction is usually about 10 µm to 15 µm. However, because the height of the probe portion on the cantilever tip is typically a few microns, and the probe is progressively thicker towards its base, it is not suited to probing holes deeper than a few microns. For example, the probe cannot reach the bottom of narrow grooves or holes with a large surface aspect ratio (ratio of width to height of the sample cross section). Therefore, care is required regarding the appearance of artifacts. Realistically, however, the observable range in the vertical direction is limited to a few microns.

Diagram of a Cantilever Probe Scanning a Sample Surface with a Large Aspect Ratio

The observable magnification levels can be calculated as the length on the displayed output divided by the corresponding length on the sample. For example, if a 125 µm length on the sample is displayed on a computer monitor or as printed output 125 mm long, then the displayed magnification is 1000x. This is the smallest magnification for general use. Making the scan range (i.e. observable range) smaller is equivalent to increasing the magnification rate. If software settings are used to specify a scan range of 0.1 nm displayed as 125 mm, for example, then the magnification would be 125 nm divided by 0.1 nm, or 1.25 billion times, which is nothing more than a calculated value. The important point for microscopes is the resolution, without which increasing the magnification arbitrarily merely results in a blurry image. With the exception of advanced research involving atoms and molecules, or observations in ultra-high vacuums, the smallest typical scan range for practical purposes is about 100 nm, which is equivalent to a magnification of about 1,000,000x (125 mm ÷ 100 nm = 1,250,000). However, since the SPM captures a digital signal, there is no worry about the magnification of the original plate as used back in the era of analog printing on photographic paper. These days, it is much more common to indicate the scan range rather than the magnification.